New Log Home Construction Company - Serving customers in Northwest Ohio, Southeast Michigan and Northeast Indiana areas.

There are a lot of things to keep track of when building a new home. Listed below are just some of the many parts of your log home that need to be addressed before you can move in.

Silver Creek Log Homes can assist you with many of these items. Depending on the location, size, and scope or your project, you may hire us to handle them, or do them yourself. You can also sub out to individual subcontractors, or hire a general contractor to do them for you. Whichever way you choose, we are there to help.

The list below is to help give you an idea of the numerous areas that will need to be considered while planning your new home. Since homes vary in design and location, you may need to add some items to this list or scratch some items off.

Silver Creek Log Homes can assist you with many of these items. Depending on the location, size, and scope or your project, you may hire us to handle them, or do them yourself. You can also sub out to individual subcontractors, or hire a general contractor to do them for you. Whichever way you choose, we are there to help.

The list below is to help give you an idea of the numerous areas that will need to be considered while planning your new home. Since homes vary in design and location, you may need to add some items to this list or scratch some items off.

Steps to Log Home Building:

- Survey of Property

- Permits

- Site Clearing

- Driveway to access home during building

- Excavation

- Foundation

- Drain Pipes for roof gutters

- Backfill

- Rough Grading

- Building of Log Home (see Materials List)

- Power washing of exterior log surface

- Application of Exterior Sealer to logs and log siding

- Application of Interior Sealer to logs

- Application of Caulk to corners and to exterior wall/soffit connection

Log Home HVAC

- Natural Gas / Propane hook-up

- Furnace, Air Conditioning, and Duct Work

Log Home Plumbing and Fixtures

- Water - Drill Well or Public water supply hook-up

- Water Softener or other treatment if necessary

- Sewer or Septic hook-up

- Rough Plumbing

- Sinks, Showers, Toilets, etc.

Log Home Wiring and Fixtures

- Electric hook-up

- Rough Wiring

- Lights, Ceiling Fans, etc.

- Phone, Computer, Cable, Alarm wiring

- Doorbells

Interior Partition Wall Covering

- Drywall, Paneling, Tongue and Groove, etc.

- Paint, Stain, or Clear Sealer

Log Home

Interior

Log Home Exterior

- Wall Finish and Insulation for gable end walls, doghouse dormers, shed dormer (if a part of your home)

- Drywall, Paneling, Tongue and Groove, etc.

- Paint, Stain, or Clear Sealer

- Interior Doors

- Interior Trim

- Cabinets and Countertops

- Kitchen

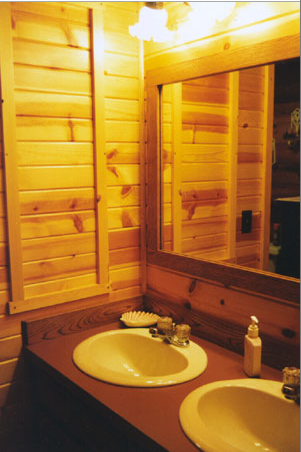

- Bath(s)

- Utility Room

- Finish Floors

- Fireplace or Wood Stove

- Appliances

Log Home Exterior

- Gutters

- Garage or other outbuildings

- Dumpster Fees

- Driveway

- Stone

- Concrete

- Asphalt

- Landscaping

- Final Grade

- Grass

- Trees / Shrubs

- Pond / Pool

Sample Log Home Materials List

Listed below are the parts of your log home that are generally included in a weather tight shell from Silver Creek Log Homes. The sections listed below are just examples. You may wish to have a conventional roof or loft system put in (use standard dimensional lumber and eliminate the exposed beams). Some of these parts may be omitted if you elect to do them yourself or hire others to do them. Some lumber grades have been omitted since spans and loading are not known. Spacing or size of structural members may need to be changed to accommodate desired load.

Subfloor

Pressure treated plate w/sill sealer

Steel plate washers to hold down sill

Beam supports-adjustable Tapco "400" Series Monoposts

Wood or steel beams as necessary

Double rim joist

Floor joists on 16" ctr.

Bridging

Exposure 1 T & G Plywood Sturdi-Floor sheeting, nailed (3" ring shank or spiral nails) and glued

Basement stairs

Eastern White Pine or Western Red Cedar log siding around perimeter of subfloor w/15# roofing felt

Steel plate washers to hold down sill

Beam supports-adjustable Tapco "400" Series Monoposts

Wood or steel beams as necessary

Double rim joist

Floor joists on 16" ctr.

Bridging

Exposure 1 T & G Plywood Sturdi-Floor sheeting, nailed (3" ring shank or spiral nails) and glued

Basement stairs

Eastern White Pine or Western Red Cedar log siding around perimeter of subfloor w/15# roofing felt

Log Wall System

Eastern White Pine or Western Red Cedar logs

Double tongue and groove

Butt & pass corners (7-8" overhang)

Window / door openings and bucks

1st floor outlet holes (for wire)

Porch light wire holes drilled next to doors

3/8" x 10" lag bolts w/ washer on approximate 32" to 36" centers

3/8" x ½" closed cell foam gasket between each course of logs

Corner and butt joint splines

Double tongue and groove

Butt & pass corners (7-8" overhang)

Window / door openings and bucks

1st floor outlet holes (for wire)

Porch light wire holes drilled next to doors

3/8" x 10" lag bolts w/ washer on approximate 32" to 36" centers

3/8" x ½" closed cell foam gasket between each course of logs

Corner and butt joint splines

Gables

Full log, or log sided w/Eastern White Pine or Western Red Cedar15# roofing felt7/16 OSB2 x 4 studs on 16" centers w/bottom and double top plate

Exterior Window and Door Trim

1 3/8" x 4 Rough Sawn Eastern White Pine or Western Red CedarDrawknifed and Sanded Northern White Cedar TrimAndersen Windows and Patio Doors

Interior Window and Door Trim

1 x 4 Rough Sawn Eastern White Pine or Western Red CedarDrawknifed and Sanded Northern White Cedar Trim

Entry Doors

Therma-Tru DoorsAdjustable Security Strike PlateHigh Performance Adjustable SillFramSaver Rot-Proof JambsDrilled for Lockset and Deadbolt

Loft

6 x 12 Select Structural or #1Douglas Fir main beams4 x 8 Select Structural or #1 Douglas Fir joists on approx. 32" ctrs.4 x 8 Select Structural or #1 Douglas Fir lower collar tiesAdjustable Tapco "400" Series Monoposts (With 6 x 6 Douglas Fir shell)2 x 6 Select SPF tongue and groove decking -nailed (3" ring shank or spiral nails) and gluedNorthern White Cedar Railings

Loft

4 x 12 Select Structural or #1 Douglas Fir stringers and treadsTreads mortise or notched into stringersNorthern White Cedar railings

Doghouse Dormers

Walls2x4 studs on 16" centers7/16" OSB15# roofing feltEastern White Pine or Western Red Cedar log siding1 ¾" x 4" Eastern White Pine or Western Red Cedar roughsawn corner trimRoof2x6 rafters & ceiling joists on 16" centers7/16" OSB30# roofing feltOwens Corning ShinglesFacia-1 x 6 or 1 x 8 Rough Sawn Eastern White Pine or Western Red Cedar as neededVenting-continuous soffit and ridge

Shed Dormers

Walls2x4 studs on 16" centers7/16" OSB15# roofing feltEastern White Pine or Western Red Cedar Log Siding1 ¾" x 4" Eastern White Pine or Western Red Cedar Roughsawn TrimRoof - See Exposed Beam Roof Section Below

Roof System

Exposed Beam Sections6 x 6 Select Structural or #1 Douglas Fir posts6 x 12 Select Structural or #1 Douglas Fir ridge beams4 x 8 Select Structural or #1 Douglas Fir rafters-approximate 32" centers4 x 8 Select Structural or #1 Douglas Fir upper collar ties

2 x 6 #2 & Better SPF tongue & groove deckingHigh density cross laminated polyethylene vapor barrierR-30 polyiso insulationAir space7/16 OSB sheeting30# roofing feltOwens Corning ShinglesAluminum flashing as neededFacia-1 x 6 or 1 x 8 Rough Sawn Eastern White Pine or Western Red Cedar as neededApproximate 16" to 18" overhangs- eaves and rakesVenting-continuous soffit and ridgex 6 #2 & Better SPF tongue & groove soffit

Porches - Exposed Beam Roof System

- Deck

- Roof

2 x 6 #2 & Better tongue & groove roof decking

30# felt

Eastern White Pine or Western Red Cedar Log siding around perimeter of deck

1/4" Heavy Duty PT lattice -cover open space between deck bottom and ground. Allows air to circulate

Northern White Cedar Railings

Interior Partition Walls

1st and 2nd floor2 x 4 or 2x6 studs on 16" centers w/bottom and double top plateSettlement space as neededCripple walls above settlement space as needed

Accessories

Freight, Caulk, Exterior Sealer (Sikkens Cetol 1 and Cetol 23), Interior Sealer (Sikkens Cetol Interior Clear Satin), Checkmate (1 gal.) w/applicator bottle, all material wrapped

All nails and screws where exposed to weather will be hot dipped galvanized. All nails and screws where exposed to weather and risk of staining wood is possible, will be Maze Double Hot Dipped Galvanized or Type 304 stainless steel. Exception: Screws used to put down 5/4 x 6 PT decking on porch decks will be Type 302 stainless steel.

Labor and heavy equipment is supplied for all above items except application of interior and exterior sealer. Caulking materials and labor is generally included, unless you wish to do yourself. Caulk is not required between log courses.

Labor and heavy equipment is supplied for all above items except application of interior and exterior sealer. Caulking materials and labor is generally included, unless you wish to do yourself. Caulk is not required between log courses.

Call or email us for log home construction services for customers in Northwest Ohio, Southeast Michigan and Northeast Indiana areas.

419-335-3221

419-335-3221 5350 County Road 16, Wauseon, OH 43567

5350 County Road 16, Wauseon, OH 43567 sales@silvercreekloghomes.com

sales@silvercreekloghomes.com

By Appointment Only

By Appointment Only